Top Tank Trends of 2025: What We’ve Learned

December 31, 2025

2025 has been an exciting year for the plastic storage tank industry. On the selling side, meaningful shifts have occurred in how companies select and ship plastic storage tanks. On the buying side, customers are becoming more and more focused on how they search, choose, and purchase these storage tanks. Across industrial, agricultural, marine, and commercial installations, the results have shown that customers are prioritizing durable design, efficient service, and customization more than ever before.

At Go-To Tanks, we’ve spent the year working with our commercial and residential clients across the U.S. to learn what’s trending, what challenges persist, and what our customers look for when choosing their water storage plastic tanks.

Here are the key lessons we’ve learned from 2025 and what they mean for tank buyers in 2026.

1. Quality of Materials: Durability Dominates

Our main finding was that plastic tanks, especially rotationally molded polyethylene tanks, remain the preferred choice amongst both B2B and B2C clients. Polyethylene is the number #1 sought after material for tanks due to its chemical resistance and longevity of quality.

Key insights from 2025:

- Buyers are placing higher importance on material performance: UV‑resistance, chemical resistance, impact strength, and long service life are now baseline requirements.

- Double‑wall or containment‑ready tanks are more frequently requested: With safety precautions, environmental regulations, and insurance standards evolving, many industrial projects now require tanks with secondary containment features.

- Buyers are more sensitive to total cost of ownership (TCO): Rather than basing their purchase decision on price alone, customers will purchase a more expensive tank for its heightened lifespan, maintenance cost, and material durability.

- Raw material pressures (e.g., polymer feed‑stocks): With global supply‑chain volatility increasing lead‑times and pricing, customers seek domestic inventory and reliable U.S. manufacturing for a more efficient and higher-quality business deal.

2. Shipping & Speed: U.S.A.-Made Advantage

One of the biggest lessons of 2025: delivery speed matters.

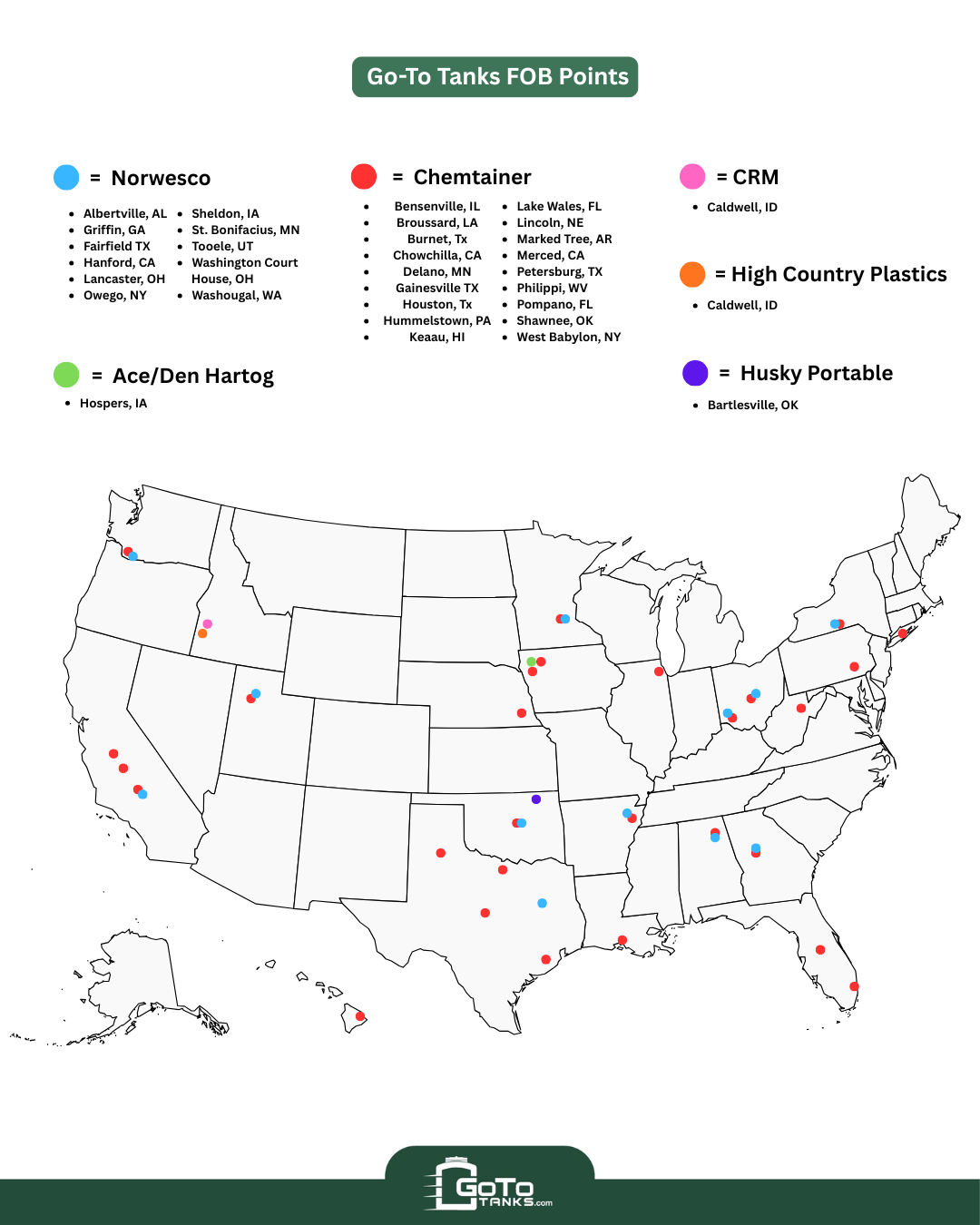

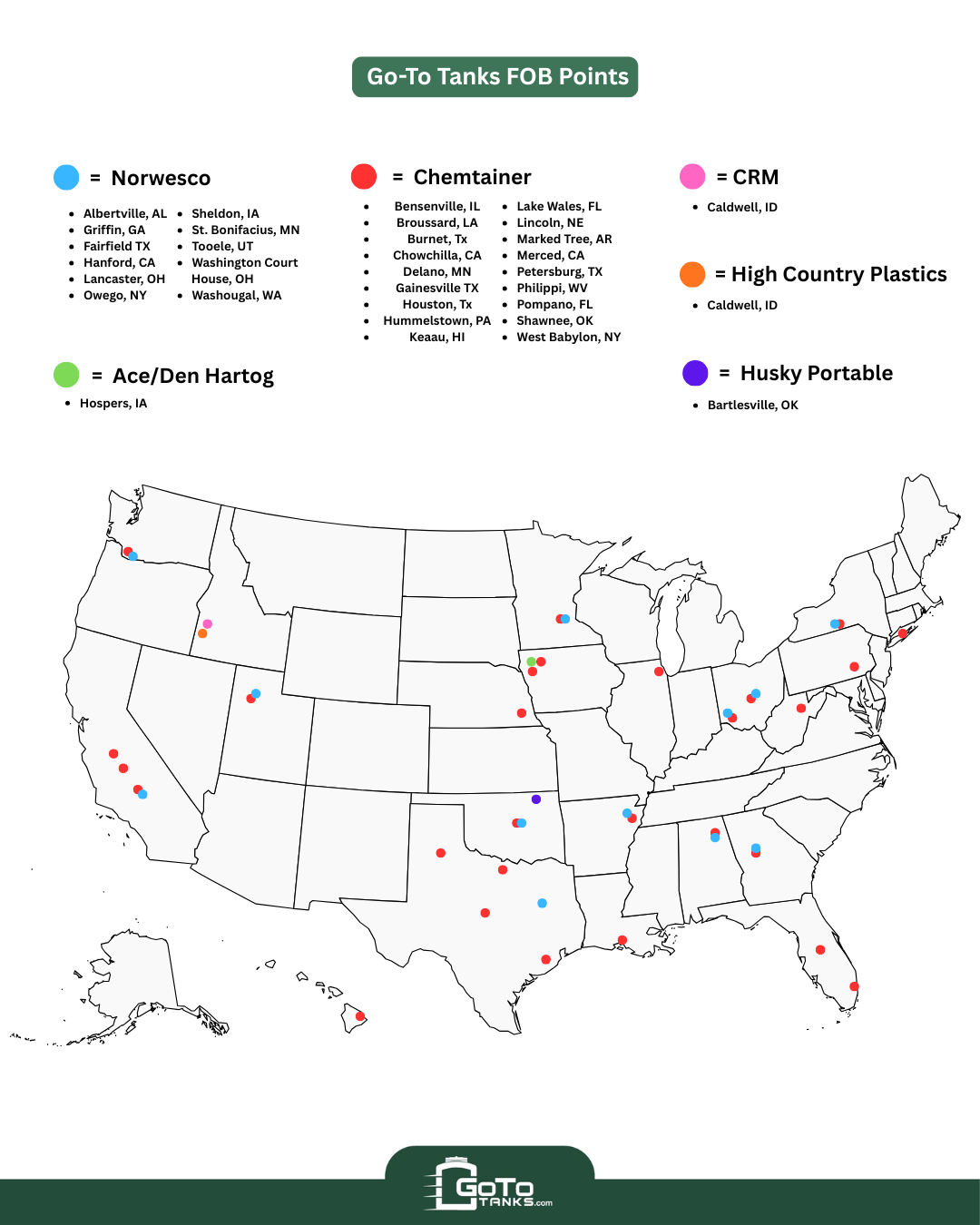

With Go-To Tanks’ multiple U.S. manufacturing locations, we can:

- Reduce lead times from weeks to days with our domestic manufacturing and multiple U.S. shipping points

- Offer wholesale shipping solutions and will-call pick up solutions to reduce delivery issues and reduce overall cost.

- Ensure tanks arrive ready to install with our direct‑to‑customer wholesale model, leading to less delays in project timelines, fewer intermediaries, clearer pricing and more consistent delivery.

Customers increasingly recognize the value of “Made in the USA” plastic tanks for quality, reliability, and faster turnaround. See below for our map of distribution.

3. Customers want Customization

This year, we noticed a clear trend: customers want custom-fit solutions.

Top tank customizations in 2025:

- Marine tanks: Smaller, rectangular tanks for fresh water storage in boats, RVs, or any other large vessel. These can be customized to fit constrained vessel geometry, specific dimensions that require special porting, or to integrate with other systems.

- Cone-bottom polyethylene tanks: Used in industrial and agricultural settings for easier liquid drainage. Industrial and chemical companies are increasingly requesting tanks with features such as cone‑bottoms, leg‑supports, multiple ports, pre‑plumbed configurations, or custom dimensions.

- Cisterns & water storage tanks: For rainwater harvesting, emergency backup, and agricultural irrigation. Agricultural and irrigation applications drive demand for durable, corrosion‑resistant plastic tanks.

Trends have reflected that customization and modular design are key emerging drivers in plastic tank markets. Custom fittings, additional ports, and pre-installed plumbing are no longer “extras”, but are now becoming standard expectations.

At Go-To Tanks, we work to make sure that any tank can be customized to any need. See our Custom Tank page to customize your tank today.

4. Technology & Industry Innovations

2025 has brought improvements in:

- Tank fittings & accessories: Buyers value increased accessory options while purchasing tanks. With a larger inventory of fittings, lids, and valves to choose from, customers will see increased value in customization for the application they’re buying a tank for.

- Manufacturing precision: Customers need reliable solutions. Tighter tolerances, standardized manufacturing, and more uniform tank shapes allows better integration with specific plumbing systems and machinery.

- Tank‑monitoring and smart technologies: customers are increasingly looking for smart tech in their tanks, such as IoT sensors, UV-inhibitors and fluid‑level monitoring.

5. Regulations & Compliance

In 2025, Industrial buyers and customers have raised demand for:

- Environmental Impact: Environmental compliance, spill containment, and chemical resistance remain key factors when selecting tanks. Some customers specifically look for recycled HDPE as their chosen tank material for its environmental value.

- Sustainability imperatives: in the 2025 Annual Trends Report, plastic‑product manufacturers face increasing pressure from regulation, and consumer demand is increasing for recycled content and circular‑economy practices.

- Regulatory compliance: the demand for higher‑grade containment solutions, chemical‑resistant tanks and secondary containment systems is increasing steadily. Businesses will need to adapt to a greener future to keep up with their customer’s preferences.

Key Takeaways for 2026

Looking ahead, here’s what businesses should keep in mind when purchasing plastic storage tanks:

1. Prioritize Durability: selecting tanks with better materials and service life reduces long‑term risk, and is more important than just a low price.

2. Customization is Key: off‑the‑shelf may fit some needs, but many installations require special features, fittings or dimensions. Go-To Tanks can customize and mold any tank to match your needs HERE.

3. Lead‑time and Logistics matter: U.S. manufacturing, transparent freight policy and reliable shipping ensures faster delivery and fewer project delays.

4. Lifecycle over Specs: installation, maintenance, regulatory compliance, and total ownership cost are more important than ever when choosing a tank.

5. Sustainability & Compliance: supporting documents, recycled content, smart‑capability readiness and regulatory fit will increasingly factor into purchasing decisions.

Go with Go-To Tanks

In 2025, the top 3 things that plastic storage tank buyers value are durability, customization, and fast delivery. In addition, new trends have emerged to reflect that customers are increasingly looking for advancements in smart‑tech capability, sustainability and regulatory readiness.

At Go-To Tanks, we remain committed to helping our customers navigate these trends and find the right tank for every application, whether it’s for industrial, marine, or agricultural use.

If you have a project in 2026, we want to help you select the right tank for your needs. Contact Go To Tanks today to explore customized, USA‑made plastic storage solutions tailored to your needs.